Premium drilling tools

OUR INSPECTION SERVICES CAN BE DONE AT THE CLOSEST NDT FACILITY OR IN THE RIG SITE

BY ONE OF ITS MOBILE INSPECTION UNITE TO MEET ANY OF THE FOLLOWING API SPECIFICATIONS:

RP7G,RP7G-2, DS-1 WITH LATEST EDITION. NDT SERVICE ALSO PROVIDES ALTERNATIVE AND CUSTOM INSPECTIONS UPON REQUEST.

A THOROUGH INSPECTION NOW WILL ENSURE THE RELIABILITY OF THE PRODUCT TO PREVENT NON-PRODUCTIVE TIME CAUSED FROM TOOLS DAMAGE.

APPLICATIONS

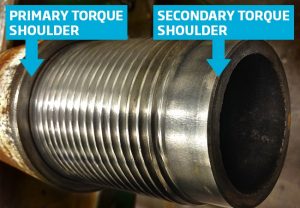

- Evaluate a shoulder damage

- Tool joint identifier

- New DP Inspection pipe rack

- Electromagnetic inspection (EMI)

DRILL PIPE INSPECTION

is carried out at regular intervals determined by the client, accepted standards and practices and dependent upon drilling conditions and past history.

ndt service: utilizes electromagnetic inspection technology (emi) units to provide mobile, electronic operations. the units allow for high speed operation and increased productivity. with its durable design and proven dependability it is engineered to meet or exceed the industry’s toughest quality standards and harshest conditions. it is capable of inspection pipe sizes ranging from 2-3/8” to 6-5/8” od; our services would supported with following check:

- visual inspection of body & threads,

- thread cleaning & dope application,

- ut wall thickness measurements & dimensional inspection,

- mpi to identify cracks & other defects,

- tool joint inspections –vt & dimensional,

- drifting assessment,

- traceability,

- quality assurance.

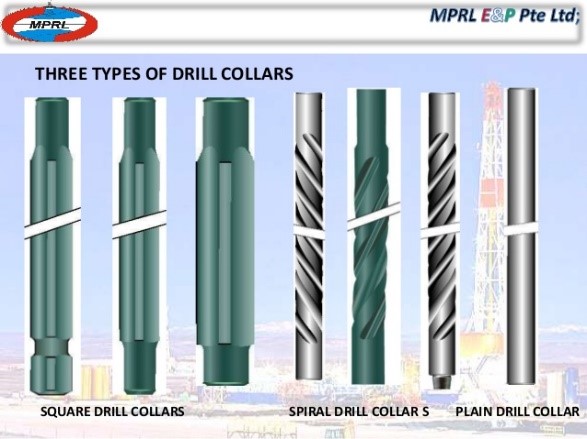

BOTTOM HOLE ASSEMBLY INSPECTION TOOLS:

NDT SERVICES; DRILL STEM TOOLS TOOLS

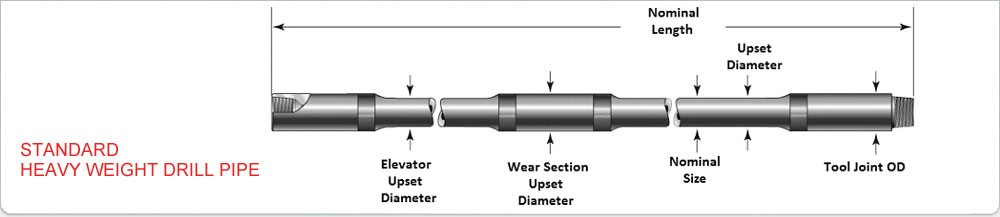

HEAVY WEIGHT RILL PIPE INSPECTION

Inspection available according DS-1 & API Standard (Drill collar and HWDP tool joint) BHA DS-1 CAT 3-5

- Visual connection

- Black light connection

- Dimensional 3

- Elevator & Slip groove

- Heat Checking

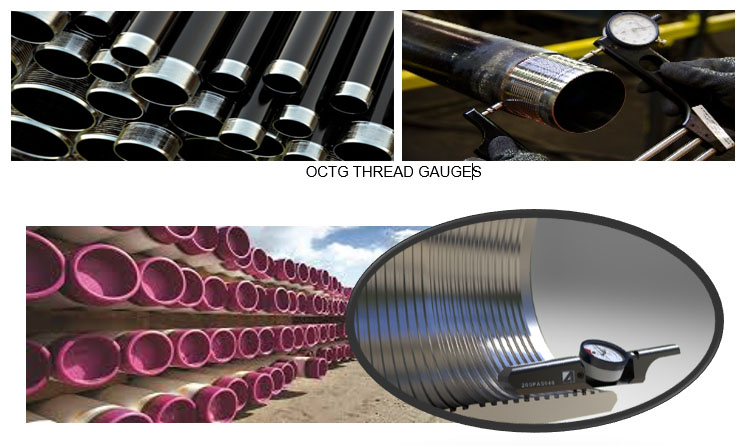

OIL COUNTRY TUBULAR GOODS (OCTG) INSPECTION

- Casing and Tubing Inspection

- Premium Connections / API Connections Inspection

- Visual Thread Inspection

- Full Length API Drift

- Full Length Magnetic Particle Examination

- Special End Area Inspection

NDT SERVICES is working to ensure compliance with international standards thread

HANDLING TOOLS

- Handling Tools play a major part in any modern drilling operation. They are used for suspending, moving and rotating tubular in and around the well center and on the drill floor.Although the majority of these tools are used to dynamically suspend and move tubulars in a vertical direction, some tools, such as the SJH elevator, serve a wider array of function by moving tubulars from horizontal to vertical position.

defaf LIBYA INSPECTION SERVICES: works to ensure the safety and security of equipment from all defects resulting from mechanical stresses and failures arising during the use and after the manufacturing process depending on the application methods adopted by the International Organization for Non-Destructive Control ASNT.

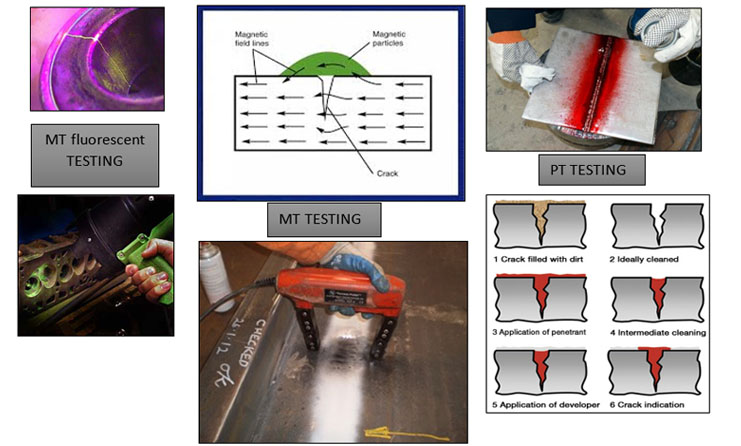

2-NON DISTRUCTIF TESTING METHODES

- Appling methods

NDT Techniques applying to SAKR LIBYA:- Visual

– MPI (magnetic particle inspection)

– DPI (dye penetrant inspection)

– EMI (electromagnetic inspection)

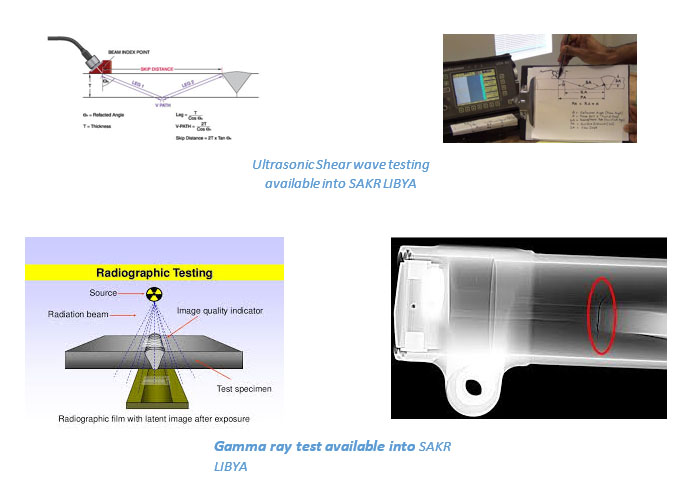

– UT (ultrasonic inspection)

-RT (radiographic testing)

REFERENCES TO defaf LIBYA INSPECTION SERVICES

- DS-1 LATEST EDITION2012 WITH 2016 ADDUNDUMAPI RP7G-2 / REFIRMED, APRIL 2015 EDITION

API RP 7G / 2004

API RP 8B EIGHTH EDITION, MAY 2014

API RP 7L REFIRMED, AUGUST 2012

API SPEC 5D FIFTH EDITION, OCTOBER 2001/ EFFECTIVE DATE: APRIL 30, 2002

ASME BVC.V-2015 ASTM E709\165

Tubular Inspection Services

Tubular Inspection includes inspection of New and Used Oil Country Tubular Goods covering Drill Pipes

• Heavy Weight Drill Pipes, Drill Collars, Casing.

• Tubing and Bottom Hole Assembly.

• Inspection Services in offer are

• Electromagnetic inspection unit – EMI for Drill Pipe Body Inspection.

• Electromagnetic inspection unit – EMI for Tubing Body Inspection.

• Electromagnetic inspection unit – EMI for Casing Body Inspection.

• Magnetic particle inspection – MPI.

• Ultrasonic Share Wave.

• Ultrasonic Thickness Gauges.

• Thread Gauging Unit.

• Straightening Machine.

• Internally Full Length Cleaning Machine.

• Externally Full Length Cleaning Machine.

• Break Out Bucking Machine.

• Visual Pipe Inspection.

• Dimensional Inspection of Pipe.

• Visual Thread Inspection.

• Tool Joint Dimensional Inspection.

• Dimensional Inspection of Rotary Shoulder.

• Wet fluorescent magnetic particle (black light) inspection.

• Dye Penetrant Testing API Full Length Drifting.

• Hardness Testing.