Introduction to tubular

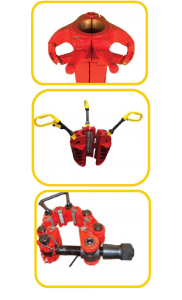

Running casing is the process of screwing together pieces of pipe on a rig floor using special equipments ; power tong, power unit and lowering them into a hole using

different handling equipments : hand slips elevator single

joint elevator etc…

During running casing,

the pipes are fitted together and lowered into the hole. A steel casing is lowered into the open hole – the action is called running casing.

TORQUE TURN SYSTEM

Torque turn system Monitor and control tubular

connection power tong make-up reliably, accurately, and easily.

•Torque turn system is a software tool that interacts with external

control hardware to provide real-time monitoring and control of

tubular connection power tong make-up. It allows you to easily

specify make-up parameters, control the make-up process, and evaluate quality.

•Using the software, you can monitor torque, turns and rotational speed during

TORQUE TURN SYSTEM

- Torque Turn Monitoring System comes with:

- Calibration management system

- Automatic “Start Recording” and “Dump Valve Release”

- Automatic descriptive comments with optional override

- Optional pressure test system is available

- Torque turn system increases the safety of your people

and givin conforms to manufacturers’ specs. You can review results

from previous make-ups and create a number of reports for

further analysis and information.

Why Defaf is the Best choice for your project?

• Excellent safety record assures least time lost from injury

• Planning, scheduling, and execution expertise assuring

on-time completion

• Resources; equipment and personnel all with one contract

• Large geographical footprint for your expansion and

maintenance

• Unique group of diversified services; one-stop contractor

for onshore,marine, and station construction expertise

Defa have the ability to

construct pipelines and piping with its different structure according to different international standards and codes such as:

• API 1104

• ASME B31.1

• ASME B31.3a

Our Pipe Welders

Our Pipe Welders Pipeline Welders, also known as Pipe Welders,

join and repair tubular products and metallic pipe components and assemblies as part of the construction of buildings, vessels, structures, and stand-alone pipeline. They use a variety of welding processes and equipment, in a wide range of industrial and commercial environments. Because pipes are routinely set up in fixed positions and situated in ways that make welding difficult, pipeline welders must be well-trained and versatile. As such, they are among the most highly skilled and sought after welders.

Safety is not a changing priority, but a Core Value

At defaf Safety is not a changing priority, but a Core Value. Safety is at the heart of every decision we make, and woven into the fabric of our culture. Everyone, from our owners, management team, and board of directors to our newest employee is constantly reminded of our commitment to Safety Excellence for ourselves, our clients, and the communities in which we work.

Full-time Division Safety Coordinators

Annual training on several topics (First Aid, CPR, Fire Extinguisher, Excavation Competent Person Training, Safe Rigging Practices, PPE, HAZCOM, Hand Tools, etc.) Training and strict adherence to company policies regarding PPE Open access to every level of management for all employees with safety concerns Open and active dialogue at all levels regarding safety issues at large Observation cards which are provided for anonymous input regarding safety issues We at GPS are confident that we have a very strong safety culture and that our management team makes this very clear to all employees on an ongoing basis. Our Team are our greatest asset, and their welfare is of paramount importance to us. The ultimate goal is ZERO Accidents. No accident or injury should be acceptable. We expect all of our employees to champion “Safety Excellence” in each and every action they take.

Codes and Standards

• Codes, Standards & Specifications

• ASME B31.1 Power piping Design,Fabrication & Inspection

• ASME B31.3 Process Piping Design, Fabrication & Inspection

• ASME VIII Div.1 Pressure Vessel design, Fabrication & Inspection

• AWS D1.1 Structural Steel Welding Code

• API 1104 Pipeline Construction

• ASME IX welding Procedure & Welder Qualification Code

• ASME V Non-Destructive Examinations Code

: مقدمة عن الأنبوب

تشغيل الغلاف هو عملية شد قطع الأنابيب على أرضية الحفارة باستخدام معدات خاصة؛ ملقط الطاقة، وحدة الطاقة وخفضها في حفرة باستخدام معدات المناولة الفرق: الرافعات اليدوية ومصعد مشترك واحد الخ … خلال تشغيل الغلاف، يتم تركيب الأنابيب معاً وحفضها في الحفرة. يتم تخفيض غطاء من الصلب في الفتحة المفتوحة – يسمى الإجراء تشغيل الغلاف.

: نظام تشغيل عزم الدوران

نظام تشغيل عزم الدوران للمراقبة والتحكم في الماكينة الملولبة لتوصيل الأنبوب، بشكل دقيق، وبسهولة

نظام تدوير عزم الدوران هو عبارة عن أداة برمجية تتفاعل مع أجهزة التحكم الخارجية لتوفير المراقبة والتحكم في الوقت الحقيقي لمكونات طاقة اتصال الأنابيب الأنبوبية. يتيح لك ذلك تحديد معلمات الماكياج بسهولة والتحكم في عملية المكياج وتقييم الجودة

باستخدام البرنامج، يمكن مراقبة عزم الدوران، وسرعة الدوران أثناء الماكياج. لديك خيار التحكم في السرعة أثناء الماكياج أيضاً. تعتمد عناصر التحكم على العزم النهائي أو المنعطف الأخير.

: نظام مراقبة دوران عزم الدوران يأتي مع

نظام إدارة المعايرة.•

“بدء التسجيل التلقائي” وتفريغ صمام التفريغ”.•

التعليقات الوصفية التلقائية مع تجاوز اختياري.•

نظام اختبار الضغط الاختياري متوفر .•

أأ. • يعمل نظام تدوير عزم الدوران على زيادة سلامة موظفيك ويمنحك المعلومات التي تحتاجها لضمان توافق الماكياج مع مواصفات الشركات المصنعة. يمكنك مراجعة النتائج من الصيغ السابقة وإنشاء عدد من التقارير لمزيد من التحليل والمعلومات